A stationary rotating drum mixer that mixes and blends the contents or chemicals inside of a closed 55 gallon drum saves time, labor and money. Drum rotators mix drum contents evenly maintaining homogeneity with less hazard and exposure to people in your manufacturing facility. Stationary drum mixers turn a drum on its side so you don't have to.

| Item# |

Item Name |

|

Qty |

Add |

| 2-5154/10-1 |

DOUBLE STATIONARY DRUM ROLLER, 10 RPM, 1 HP 1-PHASE 115/230V 60Hz MOTOR |

|

|

|

| 2-5154/10-3 |

DOUBLE STATIONARY DRUM ROLLER, 10 RPM, 1 HP 3-PHASE 208-230/460V 60Hz MOTOR |

|

|

|

| 2-5154/10-E1 |

DOUBLE STATIONARY DRUM ROLLER, 10 RPM, 1 HP EXPLOSION-PROOF 1-PHASE 115/230V 60Hz MOTOR |

|

|

|

| 2-5154/10-E3 |

DOUBLE STATIONARY DRUM ROLLER, 10 RPM, 1 HP EXPLOSION-PROOF 3-PHASE 230/460V 60Hz MOTOR |

|

|

|

| 2-5154/10-A |

DOUBLE STATIONARY DRUM ROLLER, 10 RPM, AIR MOTOR |

|

|

|

| 2-5154/20-1 |

DOUBLE STATIONARY DRUM ROLLER, 20 RPM, 1 HP 1-PHASE 115/230V 60Hz MOTOR |

|

|

|

| 2-5154/20-3 |

DOUBLE STATIONARY DRUM ROLLER, 20 RPM, 1 HP 3-PHASE 208-230/460V 60Hz MOTOR |

|

|

|

| 2-5154/20-E1 |

DOUBLE STATIONARY DRUM ROLLER, 20 RPM, 1 HP EXPLOSION-PROOF 1-PHASE 115/230V 60Hz MOTOR |

|

|

|

| 2-5154/20-A |

DOUBLE STATIONARY DRUM ROLLER, 20 RPM, AIR MOTOR |

|

|

|

| 2-5154/20-E3 |

DOUBLE STATIONARY DRUM ROLLER, 20 RPM, EXPLOSION-PROOF, 1 HP, 3-PHASE, 208-230/460V, 60Hz MOTOR |

|

|

|

| 2-5154/30-A |

DOUBLE STATIONARY DRUM ROLLER, 30 RPM, AIR MOTOR |

|

|

|

| 2-5154VS-1-115 |

DOUBLE STATIONARY DRUM ROLLER, VARIABLE SPEED 1-40 RPM, 1 HP 1-PHASE 115V 50/60Hz MOTOR |

|

|

|

| 2-5154VS-3-230 |

DOUBLE STATIONARY DRUM ROLLER, VARIABLE SPEED 1-40 RPM, 1 HP 3-PHASE 230V 50/60Hz MOTOR |

|

|

|

| 1-5-1 |

IDLER ATTACHMENT, ROLL 1-5 GALLON CAN ON 456 OR 1-5154 DRUM ROLLER |

|

|

|

| POLY-1-5154FI |

KIT, ROLL POLY DRUM ON 1-5154 SERIES, FIELD INSTALL |

|

|

|

| POLY-2-5154FI |

KIT, ROLL POLY DRUMS ON 2-5154 SERIES, FIELD INSTALL |

|

|

|

| POLY-1-5154 |

OPTION, ROLL POLY DRUM ON 1-5154 SERIES |

|

|

|

| POLY-2-5154 |

OPTION, ROLL POLY DRUMS ON 2-5154 SERIES |

|

|

|

| 1-5154/20-1 |

STATIONARY DRUM ROLLER, 20 RPM, 1/2 HP 1-PHASE 115/230V 60Hz MOTOR |

|

|

|

| 1-5154/20-3 |

STATIONARY DRUM ROLLER, 20 RPM, 1/2 HP 3-PHASE 230/460V 60Hz MOTOR |

|

|

|

| 1-5154/20-E1 |

STATIONARY DRUM ROLLER, 20 RPM, 1/2 HP EXPLOSION-PROOF 1-PHASE 115/208-230V 60Hz MOTOR |

|

|

|

| 1-5154/20-E3 |

STATIONARY DRUM ROLLER, 20 RPM, 1/2 HP EXPLOSION-PROOF 3-PHASE 208-230/460V 60Hz MOTOR |

|

|

|

| 1-5154/20-A |

STATIONARY DRUM ROLLER, 20 RPM, AIR MOTOR |

|

|

|

| 1-5154/30-A |

STATIONARY DRUM ROLLER, 30 RPM, AIR MOTOR |

|

|

|

| 1-5154VS-1-115 |

STATIONARY DRUM ROLLER, VARIABLE SPEED 1-40 RPM, 1/2 HP 1-PHASE 115V 50/60Hz MOTOR |

|

|

|

| 1-5154VS-3-230 |

STATIONARY DRUM ROLLER, VARIABLE SPEED 1-40 RPM, 1/2 HP 3-PHASE 230V 50/60Hz MOTOR |

|

|

|

| 1-5-2 |

TWO IDLER ATTACHMENTS, ROLL 1-5 GALLON CANS ON 2-5154 DRUM ROLLER |

|

|

|

| Check the items you wish to purchase, then click

|

|

More Information:

Stationary Drum Rollers

|

Single Drum Rollers for rolling one drum

|

Double Drum Rollers roll 1 or 2 drums at a time

|

|

|

|

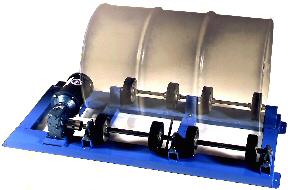

Model 1-5154/20-1 (shown) rolls your 55-gallon steel drum at 20 RPM.

|

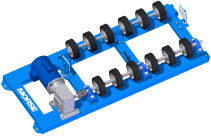

Model 2-5154/20-1 (shown) rolls your 55-gallon steel drums at 20 RPM.

|

Features

Drum rotating speed

- Choose a fixed drum rotating speed of 10, 20 or 30 RPM. The 20 RPM speed is favorable for most liquids and is furnished if RPM is not specified.

- Variable speed models supply drum rotating from 10 to 40 RPM. Speed is managed easily by turning a knob.

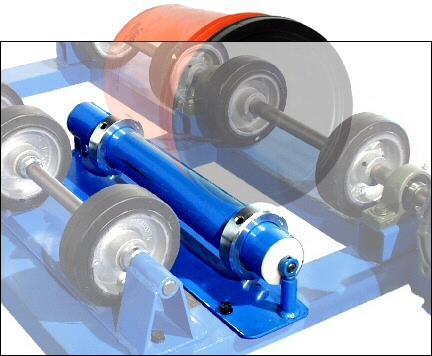

Four drive and four idler wheels per drum

Eliminate:

- Spills and splashing of dangerous contents on workers

- Risk of contamination

- Transfer and clean-up

- Special vessels and apparatus

Options for your Stationary Drum Roller Options for your Stationary Drum Roller

Options to roll a 55-gallon plastic drum on stationary drum rollers provide extra wheels to support a flexible soft sided 55-gallon plastic drum which lacks ribs or roll rings, and an end stop to prevent your plastic drum from traveling lengthways while being rolled.

- Option # POLY-1-5154 for single drum roller

- Option # POLY-2-5154 for double drum roller

Option #1-5-1: to roll a 1 to 5 gallon can

Options to roll a 1 to 5 gallon can extend the usefulness of the rotator to roll 1 to 5 gallon cylindrical cans and pails. It also comes complete with adjustable spacers and mounts .

- Option # 1-5-1 Idler Attachment

|

Floor-Mounted Single or Double Drum Roller

|

|

Single Drum Rollers

|

Double Drum Rollers

|

Single Drum Rollers

- Roll a steel drum 6” to 28” diameter and up to 40” long

- 1/2 HP motor drives efficient worm gear reducer connected to solid 1" (2.54 cm) diameter shaft to turn four 6" (15 cm) diameter Neoprene drive wheels

- Base dimensions: 24" x 55" (61 cm x 140 cm)

Variable Speed Drum Rotators (not shown)

- Similar to model 1-5154, but transmission allows user to vary drum speed from 10 to 40 RPM

- Ideal for experimental use

- Some users prefer fast initial rolling and reduced speed for continued, gentle agitation

- Handles same drum weights at corresponding speeds as fixed speed models

|

Double Drum Rollers have twice the capacity

- Roll one or two steel drums 6” to 28” diameter and up to 36” long

- Heavy-duty 1 HP motor drives efficient gear reducer connected to 1" diameter shaft operating eight 6" (15.2 cm) diameter Neoprene drive wheels

- Speed choices same as 1-5154 above

- Base dimensions: 24" x 97" (61 cm x 140 cm)

Double Variable Speed Drum Rotators (not shown)

- 1 HP, 60 Hz motor with variable speed gear reduction

- Handles same drum weights at corresponding speeds as fixed speed models

|

Standard Stationary Drum Rotators & Drum Mixers are shipped without control, cord and plug and must be installed by an electrician according to local codes and customer's preference.

Explosion Proof motors are rated for Class I Group D, and Class II Groups F and G.

Models are available with 50 Hz motors, however, expect a 20% reduction in drum RPM.

Air motors are vane-type and require correctly sized filter, regulator, lubricator, valve (FRL) and piping supplied by customer.

- Filter, regulator and lubricator (FRL) may be ordered from Morse

- Part # 90010-P Description: KIT, 1/4" FRL & VALVE

- Part # 90020-P Description: KIT, 3/8" FRL & VALVE

Install Rotators in accordance with OSHA requirements for enclosure and interlock, etc. For OSHA compliance, see OSHA subpart O.1910.212 "General Requirements for all Machines." Power connections and motor controls must comply with applicable codes. Install Rotators in accordance with OSHA requirements for enclosure and interlock, etc. For OSHA compliance, see OSHA subpart O.1910.212 "General Requirements for all Machines." Power connections and motor controls must comply with applicable codes.

Product Documents:

|

|