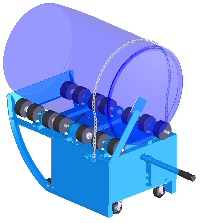

Morse 55-Gallon (210 liter) Portable Drum Rollers, Drum Rotators or Drum Mixers mix the contents of sealed drums. Compact, industrial drum mixers roll closed drums on their side and agitate the contents quickly so you don't have to. Eliminate worker exposure and reduce clean-up by getting rid of the insertion mixer. You won't even have to open the drum to mix stratified or settled ingredients. You'll be able to get all the sediments off the bottom of your drums conveniently and not waste any valuable chemicals that might have gone unmixed.

| Item# |

Item Name |

|

Qty |

Add |

| 1-5P |

IDLER ATTACHMENT, ROLL 1-5 GALLON CAN ON 201 |

|

|

|

| POLY-201FI |

KIT, ROLL POLY DRUM ON 201, FIELD INSTALL |

|

|

|

| POLY-201 |

OPTION, ROLL POLY DRUM ON 201 |

|

|

|

| 201B/20-1 |

PORTABLE DRUM ROLLER, 2 BELTS, 20 RPM, 1-PHASE 115 MOTOR |

|

|

|

| 201B/20-3 |

PORTABLE DRUM ROLLER, 2 BELTS, 20 RPM, 3-PHASE MOTOR |

|

|

|

| 201B/20-A |

PORTABLE DRUM ROLLER, 2 BELTS, 20 RPM, AIR MOTOR |

|

|

|

| 201B/20-E1 |

PORTABLE DRUM ROLLER, 2 BELTS, 20 RPM, EXPLOSION-PROOF 1-PHASE MOTOR |

|

|

|

| 201B/20-E3 |

PORTABLE DRUM ROLLER, 2 BELTS, 20 RPM, EXPLOSION-PROOF 3-PHASE MOTOR |

|

|

|

| 201/20-1 |

PORTABLE DRUM ROLLER, 20 RPM, 1-PHASE 115V MOTOR |

|

|

|

| 201/20-3 |

PORTABLE DRUM ROLLER, 20 RPM, 3-PHASE MOTOR |

|

|

|

| 201/20-A |

PORTABLE DRUM ROLLER, 20 RPM, AIR MOTOR |

|

|

|

| 201/20-E1 |

PORTABLE DRUM ROLLER, 20 RPM, EXPLOSION-PROOF 1-PHASE MOTOR |

|

|

|

| 201/20-E3 |

PORTABLE DRUM ROLLER, 20 RPM, EXPLOSION-PROOF 3-PHASE MOTOR |

|

|

|

| 201VS-1 |

PORTABLE DRUM ROLLER, VARIABLE SPEED 10-24 RPM, 1-PHASE 115V MOTOR |

|

|

|

| 201VS-3 |

PORTABLE DRUM ROLLER, VARIABLE SPEED 10-24 RPM, 3-PHASE MOTOR |

|

|

|

| 201VS-A |

PORTABLE DRUM ROLLER, VARIABLE SPEED 10-24 RPM, AIR MOTOR |

|

|

|

| 201VS-E1 |

PORTABLE DRUM ROLLER, VARIABLE SPEED 10-24 RPM, EXPLOSION-PROOF 1-PHASE MOTOR |

|

|

|

| 201VS-E3 |

PORTABLE DRUM ROLLER, VARIABLE SPEED 10-24 RPM, EXPLOSION-PROOF 3-PHASE MOTOR |

|

|

|

| Check the items you wish to purchase, then click

|

|

More Information:

Morse Portable Drum Rollers & Drum Mixers

Eliminate spills, unevenly mixed contents, and wasted chemicals from half-mixed 55 gallon drums. Portable drum rollers make your life easier and more efficient by mixing the contents of 55 gallon barrels safely & easily. Compact, portable industrial drum mixers and drain stands agitate the contents of drums in your shop or manufacturing facility with less hassle. Let Morse Drum Handling equipment make your job easier.

Mix the contents of a sealed drum faster, eliminate worker exposure to harsh chemicals and reduce clean-up of potentially toxic materials.

Use the kickstand to prop the drum

roller on end. Then place your drum

onto the base plate with a drum truck

or a below-hook drum lifter.

|

- Portable drum mixers agitate and blend drum contents without opening the drum

- Ability to utilize important ingredients that would otherwise be in unmixed sediment

- Gets rid of hazards and clean-up of messy transfer of contents

- Drum roller

- 6" to 28" in diameter

- Up to 40" tall

Note: The tipping lever will only engage a drum 30" or taller

- Capacity varies with model number

- 55 gallon drum roller

- 500 Lb. Liquid Load

- Up to 400 Lb. Dry Load. A shifting dry load exerts greater stress on the drum rotator.

- When ordering specify choice of drum RPM and motor type

- Dimensions

- Stands just 19.25" tall when rolling a drum, making loading and unloading easier.

- Measures 21" wide x 34.75" long with drum in rolling position.

|

The built-in retractable tipping

lever assists in loading a heavy

drum onto the drum roller.

|

- To assist loading there is a built-in retractable tipping lever (shown left)

- Ability to use as drain stand to dispense from drum

- Enclosed sides and back protect the drive

- Available motor options

- Single or 3 phase electric 55-gallon drum mixers

- Explosion proof

- Air powered

- Fixed-Speed Portable Drum Rollers - Choose a portable drum roller to rotate drum at single speed of 10, 20 or 30 RPM

- Variable-Speed Portable Drum Rollers - Transmission that allows you to vary drum speed from 10 to 24 RPM

- Ideal for experimental use

- Some users prefer fast initial drum rolling, then reduced speed for continued, gentle agitation

|

Morse Model 201/20-1 Portable Drum Roller rotates a 55 gallon drum at 20 RPM

|

|

Fixed-Speed Morse Portable Drum Roller Models

Choose a Morse portable drum roller to rotate drum at single speed of 10, 20 or 30 RPM

Variable-Speed Morse Portable Drum RollersMorse Portable drum rollers with a transmission that allows you to vary drum speed from 10 to 24 RPM

- Ideal for experimental use

- Some users prefer fast initial drum rolling, then reduced speed for continued, gentle agitation

Belted Morse Portable Drum Roller for Fiber Drum

|

The belted drum rollers have a pair of belts between the rollers to turn drum (instead of 2 rows of wheels). Belts allow it to roll a fiber drum weighing up to 300 Lb. without damaging the fiber sidewall.

Belted portable drum rollers are available with same drum speed and motor types.

|

Options

Option # 1-5P Idler Attachment to Roll a 1 to 5 Gallon Can

|

|

-

Extends usefulness of rotator to roll 1 to 5 gallon cylindrical cans

-

Comes complete with adjustable spacers and mounts

-

This option is for 201 and 201VS portable drum rollers

-

Not for 201B series belted drum rollers

-

Also see 5-Gallon Can Tumblers designed specifically to tumble 1 to

5 gallon cans / pails end over end to mix the contents more vigorously

|

Option # POLY-201 to Roll a Plastic Drum

|

Plastic drums are soft-sided and lack the ridged ribs and rims of a

steel drum. These plastic drums require special features to position them on the drum

roller, and to prevent them from traveling lengthways during rotation.

This option includes

-

Three extra wheels on each side support your plastic drum. The weight is then distributed over a total of 14 wheels.

-

End stop to prevent a plastic drum from traveling lengthways while being rolled.

-

Chain to latch around the top of the drum while tipping from

upright to horizontal rolling position on the drum rotator. During drum rolling, the chain should then be released.

Option # POLY-201

Order this option factory installed on your new portable drum roller.

Option # POLY-201FI

Kit for field installation to roll a plastic drum on your existing portable drum roller.

|

Option # 201-CAGE Enclosure with Safety Interlock

Place your drum roller into the cage and close it to begin rolling. When the cage is opened, the drum roller is automatically shut off.

Install Morse Rotators in accordance with OSHA requirements for enclosure and interlock, etc. For OSHA compliance, see OSHA subpart O.1910.212 "General Requirements for all Machines." Power connections and motor controls must comply with applicable codes. Install Morse Rotators in accordance with OSHA requirements for enclosure and interlock, etc. For OSHA compliance, see OSHA subpart O.1910.212 "General Requirements for all Machines." Power connections and motor controls must comply with applicable codes.

|

How To Order Portable Rotators

|

|

Series

|

/

|

RPM

|

-

|

Explosion Proof:

add "E"

|

Motor Type

(1 phase, 3 phase, or Air)

|

|

201

|

/

|

10, 20 or 30

|

-

|

|

1, 3 or A

|

|

201B (Belted)

|

/

|

10, 20 or 30

|

-

|

|

1, 3 or A

|

|

201VS (Variable Speed)

|

-

|

|

|

|

1, 3 or A

|

|

201BVS

(Belted Variable Speed)

|

-

|

|

|

|

1, 3 or A

|

|

Example Model #

|

Description

|

|

201/20-E1

|

Portable Rotator, 20 RPM, Explosion Proof, Single Phase

|

|

201VS-A

|

Portable Rotator, Variable Speed, Air Motor

|

Morse Portable Drum Rotators with standard 1/2 HP, 60Hz, 1 phase TEFC motor include switch, cord and plug. All other electric 55 gallon drum rollers (i.e. Explosion proof, air powered, 3 phase, etc.) are shipped without switch, cord and plug. These must be installed by electrician according to local codes and customer's preference.

Explosion Proof motors are rated for Class I Group D, and Class II Groups F and G.

Models are also available with 50 Hz motors, however, expect a 20% reduction in drum RPM.

Air motors are vane-type and require correctly sized filter, regulator, lubricator, valve (FRL) and piping supplied by customer.

Filter, regulator and lubricator (FRL) may be ordered from Essex Drum Handling as Part # 90010-P Description: KIT, 1/4" FRL & VALVE

Product Documents

|

|